All Categories

Contact Us

-

Phone

0531-83312934 -

E-mail

[email protected] -

Address

#213, Century Avenue, Mingshui Economic Development Zone, Zhangqiu District, Jinan City, Shandong Province, China

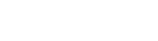

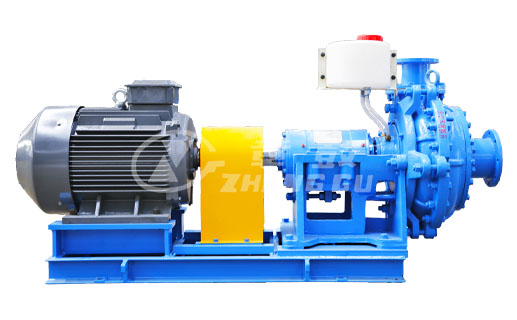

TZJKT series ceramic slurry pump, whose material of the wet parts is ceramic, developed by Shandong Zhangqiu Blower Co., Ltd. on the basis of TZJ series slurry pump and combined with the latest ceramic technology, has obtained the national patent for the invention.

Product introduction:

TZJKT series ceramic slurry pump, whose material of the wet parts is ceramic, developed by Shandong Zhangqiu Blower Co., Ltd. on the basis of TZJ series slurry pump and combined with the latest ceramic technology, has obtained the national patent for the invention.

The material of the wet parts is wear-resistant ceramics with high cavitation resistance and long life. The service life of ceramic wet parts is three times that of wear-resisting metal wet parts.

Shaft seal can use expeller with a combination of mechanical seal, which is the patented sealing technology of the company. Another traditional sealing way is using expeller with a combination of packing seal.

Applications:

★The feeding of metal ore dressing plant (gold, silver, copper, iron, lead, etc.) and the transport of various concentrates, tailings and various dense materials;

★The feeding of non-metallic ore beneficiation plant (such as phosphate ore) and the transport of various concentrates, tailings and various dense materials;

★Transportation of various abrasive slurries in the production process of titanium dioxide, iron powder, phosphate fertilizer, and potassium fertilizer.

Main features:

★ The wear resistance of ceramic is more than 3 times that of high-chromium wear-resistant alloys, and the hardness is up to Mohs hardness 9, after diamond;

★ The pump impeller is designed with the world’s most advanced Solid-Liquid Two Phase Flow velocity ratio theory, which is very efficient;

★ The shaft seal can use the our unique “self-circulating cooling mechanical seal” patent technology, which has no packing, no leakage and does not need maintenance. Another shaft seal way is using auxiliary impeller with a combination of packing seal.

★ The high hardness of ceramic wet parts is not affected by the damage of cavitation and has long service life;

★ Ceramic wet parts wear slowly, which can reduce the fluid loss of the pump and save energy.

Parameters and working conditions for the pump:

Quantity: 50-2000m³ / h;

Head: 10-100m;

Technical data of ceramic slurry pump:

|

Model |

Size range (discharge) (mm) |

Diameter range of impeller (mm) |

Q Capacity (m3/h) |

H Head (m) |

n Speed (r/min) |

Pump weight (kg) |

|

TZJK |

50–300 |

330–700 |

50–2000 |

10–100 |

490–1480 |

400–5000 |