All Categories

Contact Us

-

Phone

0531-83312934 -

E-mail

[email protected] -

Address

#213, Century Avenue, Mingshui Economic Development Zone, Zhangqiu District, Jinan City, Shandong Province, China

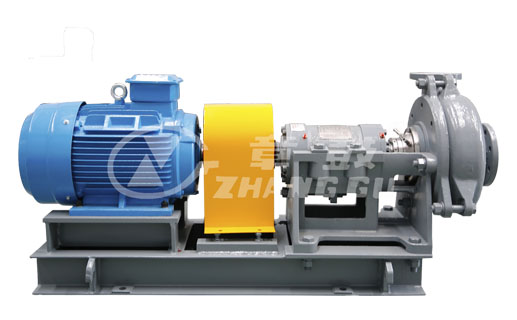

Product introduction:

The anti-corrosion and wear-resistant ZGTX series, ZGT series, TZ series desulfurization pumps are new generations of high-efficiency and energy-saving pumps jointly developed with domestic well-known universities. They are researched on the basis of the actual characteristics of China’s wet flue gas desulfurization industrial mines after analyzing advantages and disadvantages of similar products at home and abroad. These series of pumps have a wide range of applications, and are suitable for the transportation of solid-particle-containing flue gas desulfurization in power, steel, coal, alumina, smelting, papermaking, building materials and other industries. It can be used as FGD device absorption tower slurry circulation pump, limestone slurry pump, gypsum slurry delivery pump, wastewater pump, emergency slurry pump, etc. In addition, our company also provides TIH series process water pumps, TDQ series submersible pit pumps and TZJL series submersible pumps.

Structure features:

1, The impellers, volute casing, guard plates and other wet parts fluid molded lines of ZGTX desulfurization absorption tower slurry circulating pump, ZGT series desulfurization slurry pump, TZ series standard chemical process pump adopt solid-liquid two-phase flow hydraulic models developed by well-known domestic universities based on China’s FDG characteristics. This design makes pumps more efficient and more suitable for FGD absorption tower slurry circulation and the operating conditions of slurry delivery pump. Field practice has proved that our products are cavitation-resistant and have no concentrated wear. The efficiency and abrasion-resistance ability of our pumps are higher than the current FGD on-site desulfurization pump!

2. ZGTX absorption tower desulfurization slurry circulation pump provides various materials such as Cr30, CD-4MCu, 2605, 2205, 304, 316, and 316L according to different working conditions. The wet part components are of all-metal construction, which has less water friction, and they are more efficient than the non-metal pumps with the same parameter. Its geometric dimensions are easy to control; its spare parts have smooth surfaces; the gap between the parts is small; its volumetric efficiency is high; and the overall efficiency is higher than that of the nonmetal pump.

3. In the sealing structure of ZGTX absorption tower desulfurization slurry circulation pump, wear-resistant plates are used to replace the choma, because the wear of the choma by the slurry will result in a rapid decline in pump efficiency. The diameter of the pump shaft is large and the cantilever is short, which reduces the deflection of the shaft during operation, thereby extending the service life of the seal. The pump is arranged in a back-pull structure with an extended diaphragm coupling, which is easy to maintain. When the impeller, mechanical seal and shaft assembly are removed, the whole set of rotor parts can be pulled out from the motor end without removing the inlet and outlet pipeline of the pump and the motor. The shaft seal is a combination structure of mechanical seal and back blade. The back blade can prevent solid particles from entering the mechanical seal so that to extend the service life of the mechanical seal. The cartridge mechanical seal is easy to disassemble and replace. The rotating and static rings are both silicon carbide, which is more suitable for the sealing of slurry media. The material of static seal is PTFE; other metal parts are not in contact with the medium to avoid corrosion of the mechanical seal.

Technical data of desulphurization pump

|

Model |

Size range (discharge) (mm) |

Diameter range of impeller (mm) |

Q Capacity (m3/h) |

H Head (m) |

n Speed (r/min) |

Pump weight (kg) |

|

ZGT |

25–550 |

250–750 |

5–4000 |

10–60 |

490–1480 |

200–8000 |